The Quick Installation of Industrial Steel Buildings

In today’s fast-paced world, industrial steel buildings have become a popular choice amongst industries. Not only are they valued for their durability but also the speed of their installation. Steel is a great material to work with because of its unmatched strength and ability to be prefabricated. In this article, we’ll explore the quick installation process that makes these buildings a top choice for industries.

Why Steel is Best for Construction?

Industrial steel buildings are structures made from steel that are designed to be durable. They are used for industrial purposes and assist in industries, such as warehouses, storage, manufacturing and commercial buildings. They are known for their open floor space and high ceilings, which accommodate various manufacturing processes and layouts.

Why Steel is Best for Construction?

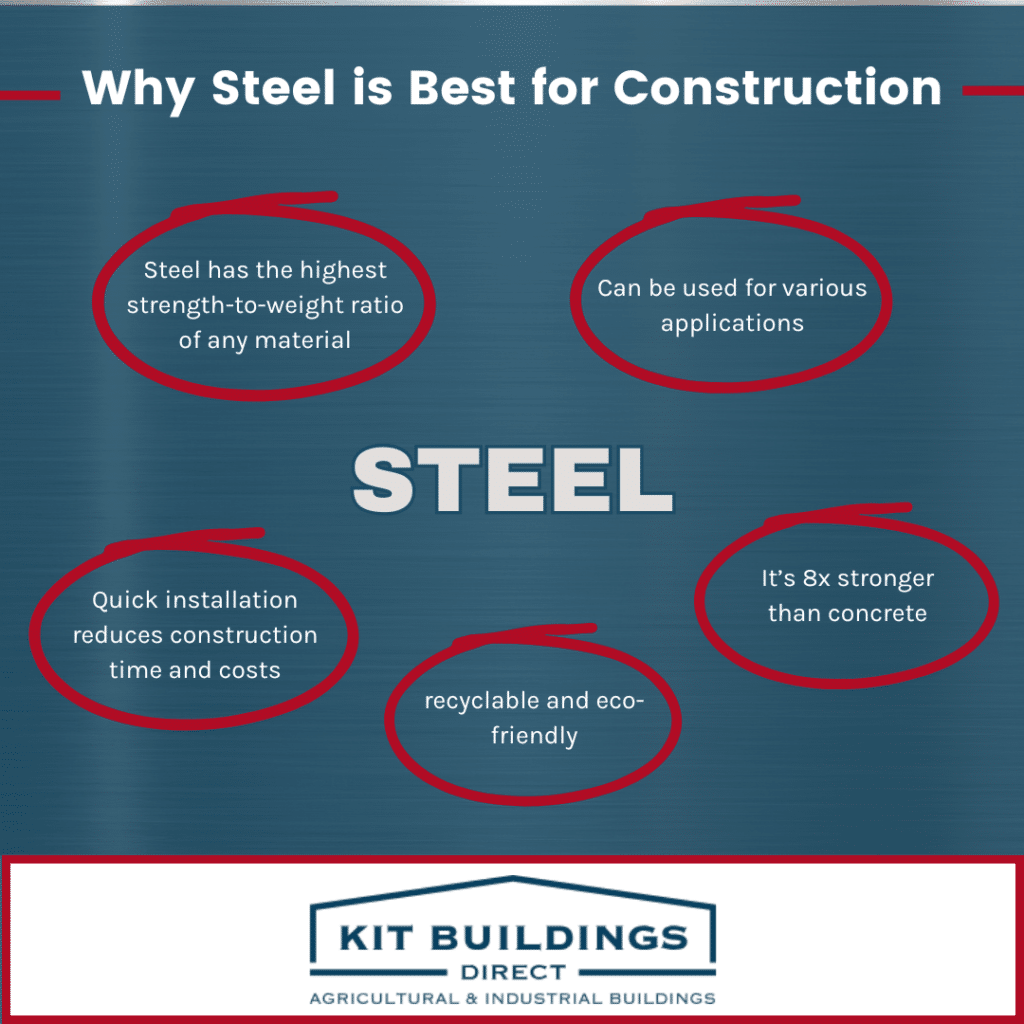

If you’re looking for a reliable and durable construction material, you won’t find a better one than steel. Steel-framed buildings are one of the most popular choices for commercial and industrial applications for a number of reasons.

Durability and Strength

Steel can withstand heavy loads and strong impacts without deforming or collapsing. It has the highest strength-to-weight ratio among building materials and is eight times stronger than concrete. This strength gives these structures a long life span. It also provides stability and safety for the building’s occupants.

Cost-effectiveness

Steel is a cost-effective material. Due to its high strength-to-weight ratio, less steel is needed in a single support or beam, which helps lower material costs. Additionally, the quick installation process of steel buildings significantly reduces the overall construction time. This saves both time and expenses.

Sustainability

Steel is a highly sustainable material. It is fully recyclable, which means it can be reused or repurposed. Compared to other building materials, steel also requires relatively low energy to produce.

Versatility

Steel is a versatile material that can be formed into a variety of shapes. This adaptability makes it easy for engineers and builders to create strong, stable structures that can support heavy loads. This versatility allows steel to meet the diverse needs of different construction projects.

Advancements in Prefabrication

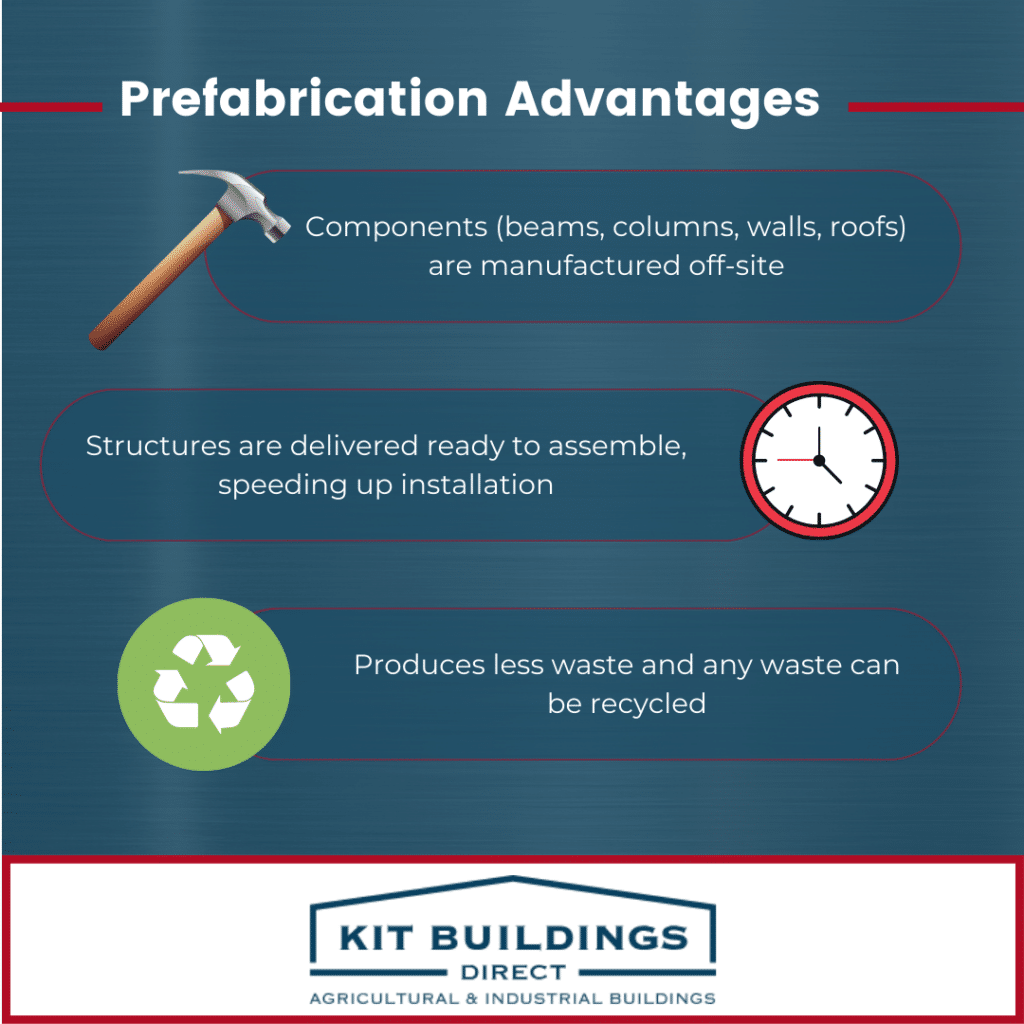

One of the most enjoyable benefits of steel industrial buildings is they can be prefabricated. This means the components of the building, such as beams, columns, walls and roof panels, are manufactured off-site. This is done in a controlled factory environment before it’s transported to the construction site for assembly. Steel building installations are a quick and easy process because of this.

Having the pieces arrive at your site ready to be installed is highly convenient compared to traditional building materials such as concrete. These are usually fabricated on-site in a slower step by step process. Steel installation also produces less waste than concrete and any waste that is produced can be recycled.

Installation Process of Industrial Steel Buildings

Site Preparation and Planning

At Kit Buildings Direct, we provide a quick and efficient installation process. Before the installation of your steel structure, you can work closely with our design team to customise features that will work best for your requirements.

After making sure you have the necessary permissions and meet all legal requirements for your industrial steel building, site preparation can begin. This would involve evaluating the location for suitability. Once a location has been confirmed, any obstructions and debris can be cleared. Another important step in setting up the site is to level the ground to create a stable and even foundation.

Manufacturing

Once we have come up with your ideal design, we can begin manufacturing the components of your industrial building. All of our steel work is manufactured to CE-marked standards in our Derby workshop and can either be galvanised or painted.

Delivery and Assembly

Once manufacturing and any foundation work is completed, we can transport the components and begin assembling them on-site.

Final Touches

Adding insulation, doors, windows and other features are the final steps in completing your steel building. These can be customised to meet your unique requirements.

We also offer the option to install mezzanine floors, which will allow you to fully utilise the height of the building. Additionally, you can choose to add cladding to the exterior walls and roof. This extra layer not only provides greater protection against harsh weather conditions but also improves the building’s insulation.

The time required to design, build, customise and install your steel industrial building varies based on several factors. This includes size, complexity and unforeseen circumstances such as weather conditions. Larger industrial structures will typically take longer than a smaller one. However, steel buildings are known for their quick construction times and can often be completed in just a few weeks or several months.

Quick Industrial Steel Building Installation at Kit Buildings Direct

At Kit Buildings Direct, we take pride in installing high-quality industrial steel buildings, working together with our clients to fit their time scale. This swift turnaround has been highly beneficial to many customers who need their projects completed quickly.

We offer a range of structures, including warehouse, manufacturing, commercial and storage buildings. We are committed to quality and offer CE-marked manufacturing, along with services such as mezzanine floor installations. Customisable options such as cladding and insulation are also available. Contact us today for a quick installation process and trust us to manage every part of your project.